Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

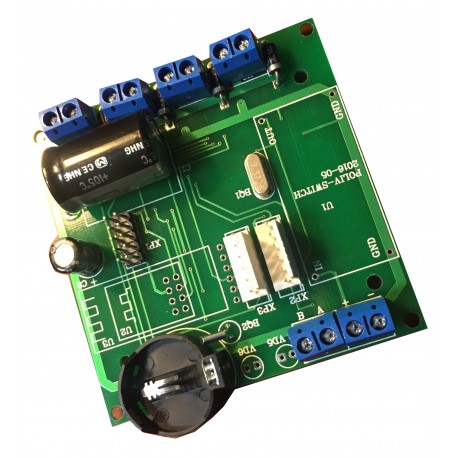

YANTAR 9W Irrigation Controller

The proposed program-tools package allows you to immediately begin working with the CNC machine. Master decided to acquire a milling machine CNC, usually has problems in the selection of the control program. Standard solution - control via parallel port and software MACH3. We offer an alternative - using of any computer with a USB input.

This product is no longer in stock

Specifications

| Number of connected valves (faucets) | 1..4 |

| DC supply voltage, V | 12..36 |

| Maximum current of the open the valve, A | 3 |

| The amount of air temperature and humidity sensors DT-11 | 1 |

| The number of temperature sensors DS18B20 | up to 4 |

| Number of analog sensors (humidity, precipitation) | up to 2 |

| Power consumption, W, no more | 4 |

| Ingress protection (IP) | IP55 (IP65 - Bluetooth version) |

More info

Master decided to acquire a milling machine CNC, usually has problems in the selection of the control program. Standard solution - control via parallel port and software MACH3. Further accounts:

• to place the workplace bulky computer with legacy parallel port;

• install it Windows XP - not for sale now;

• buying program MACH3;

• Set crack, as usual, with the vaguely translated English terms;

• about a year to spend on mastering the intricacies and details of the interface

• break his head over how to translate a simple drawing into a format understood by the machine;

• search through the internet to choose the speed cutters and cutting speed.

We offer an alternative:

• the workplace - a compact laptop;

• Windows from XP to 10 or Linux from Ubuntu 10.04 to Mint17;

• CNC-Yantar management program - originally Russian/English language;

• You can start work almost immediately - just enough to read the step by step description of the program functions.

As a bonus, three free utilities.

CAM-Yantar - in graphic mode allows you to draw drawings. Plans stored in a format understandable machine (G-code).

CALC-Yantar - allows you to choose cutting data depending on the diameter of the cutter and workpiece material. The calculation results are stored in a convenient tabular form. Thus, and in a year you do not forget how to handle the rare material.

Spindel utility allows you to configure the program to work with any inverter support MODBUS interface.

The proposed program-tools package allows you to immediately begin working with the machine.

Before buying you can make sure the application is compatible with your computer - it is to install the program following the description. Without the controller software will run in demo mode.